Qingdao Magnet Magnetic Material Co., Ltd.

- The company was established in 2014 and its registered address is

Qingdao, China

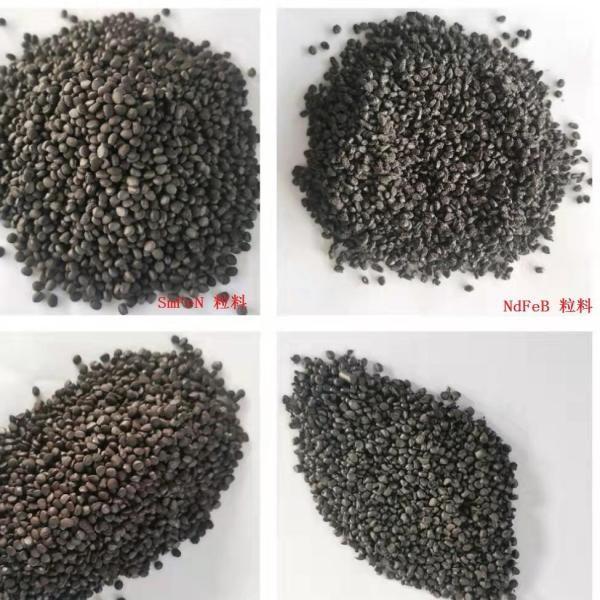

- The company's main products are: Rare earth metals, Rare earth

magnetic powder, Rare earth NdFeB Compound, Rare earth

Samarium-Iron-Nitrogen Compound, Various magnetic materials: Bonded

NdFeB Magnets,Injection molding NdFeB Magnets, Injection

molding SmFeN Magnets,Sintered NdFeB Magnets, magnetic Assemblies;

- The current annual sales are 20-25 million RMB or 3-4 million US

dollars

- Magnetic powder and rare earth metal sales accounted for 50%;

Particles and magnetic materials accounted for 30%; Magnetic

Assemblies: 20%

- We have R&D and manufacturing capabilities from rare earth

magnetic powder to magnetic materials

- At present, we provide high-quality products to customers in China,

Japan, Korea, Germany and other countries.